The human-machine interfaces (HMIs) in an aircraft do more than relay information. They connect passengers to the crew and the crew to the aircraft. The right design and implementation of HMIs create the foundation for an optimal experience.

The passenger experience is one of the most important factors in designing an onboard human-machine interface, but HMIs go beyond allowing passengers to control their seats, adjust their lighting, and select their in-flight entertainment. HMIs are also essential for pilots and crew to perform their duties.

The design and features of HMIs, such as backlighting, the type of feedback provided, and the feel of materials, make critical contributions to the final design. The challenge for aerospace manufacturers is twofold: to incorporate HMIs in ways that are intuitive, and to do so in ways that make them easy to integrate into the overall design concept while respecting engineering constraints and aesthetic concerns.

The HMI Challenge: Meeting Aerospace Industry Standards While Improving the User Experience

It is also important to understand human-machine interface requirements in the context of time and space – it’s not just about designing human-machine interfaces for today’s passengers, but designing interfaces that will meet the needs and demands of the future of air travel.

In commercial airplane cabins, the limitations on available space are baked-in design constraints, which greatly limited HMI options in the past. Add to those the need to ensure that HMIs meet industry and manufacturer standards, including meeting rigorous quality and reliability protocols while providing the required protection against shock and vibration, and the result is the previous generation of HMIs, full of limitations and shortcomings.

Thankfully, advancements made in materials and design now permit interfaces that can make use of these hitherto underused spaces to integrate the next generation of aerospace industry compliant HMIs, ones that will continue to optimize the passenger experience.

Using Technical Innovation and Design Expertise to Improve the User Experience

The most successful HMI designs integrate ergonomics, technical specifications, and engineering constraints in subtle ways to create interfaces that are not only aesthetically pleasing but also maximize ease of use and versatility.

In modern aircraft cabins, HMIs have an important role to play in passenger control units and seat controls, in-flight entertainment controls, galley controls, signage and indicators, lighting, as well as the abundant possibilities for customized touch screen solutions to HMI challenges.

Custom HMIs from E2IP TECHNOLOGIES

Here are just a few examples of how our aerospace products have made the lives of airline passengers easier:

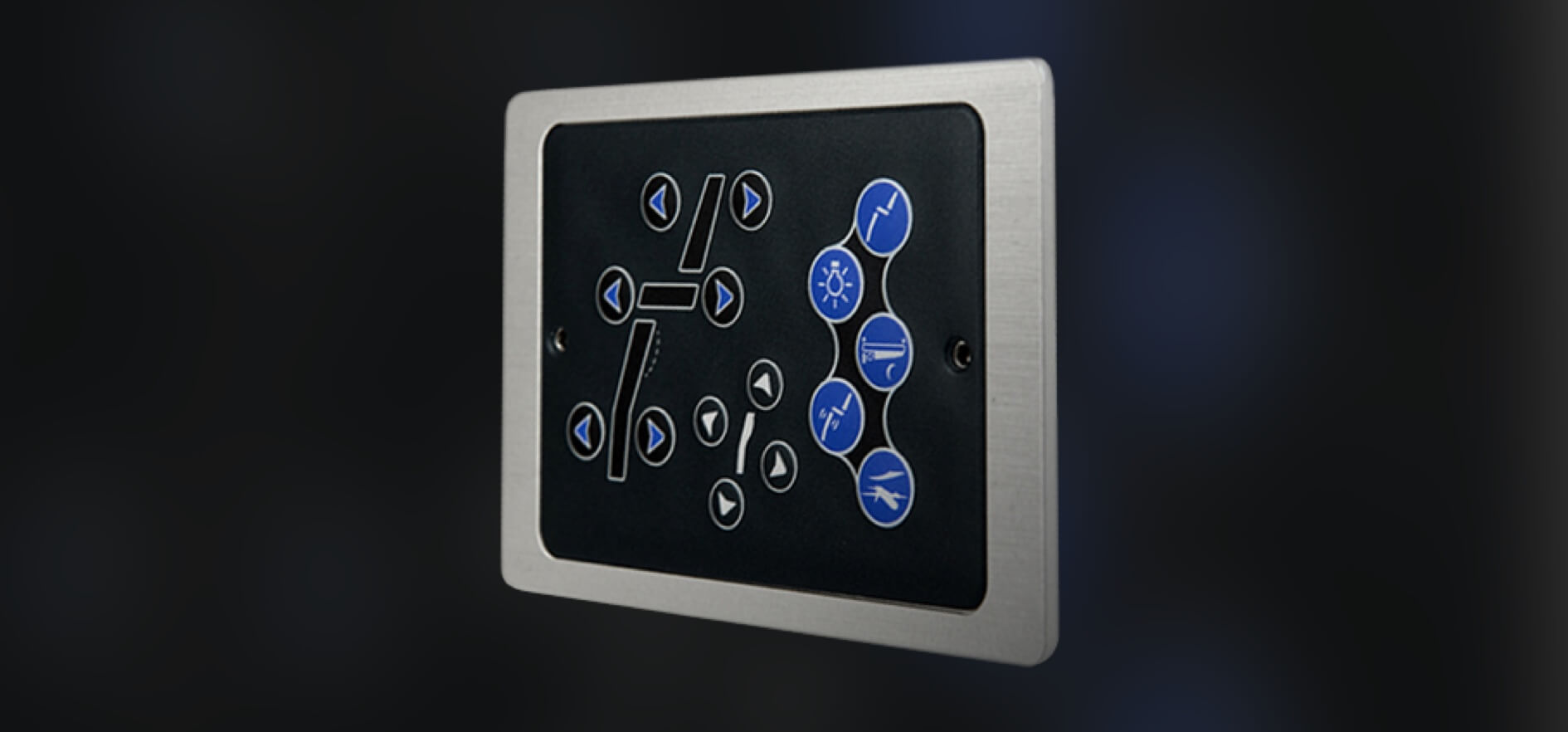

Passenger Control Units (PCU) & Seat Controls

Airplane seats are fundamental to the comfort and overall enjoyment of passengers during their travel experience. As such, designers and engineers pay special attention to the desires of passengers in this area, creating ergonomic, intuitive and customizable PCUs and seat controls.

These robust and reliable products can be tailored to complement our customer’s interior designs with optically balanced and uniform backlighting in various colors, patterns, textures, and icons.

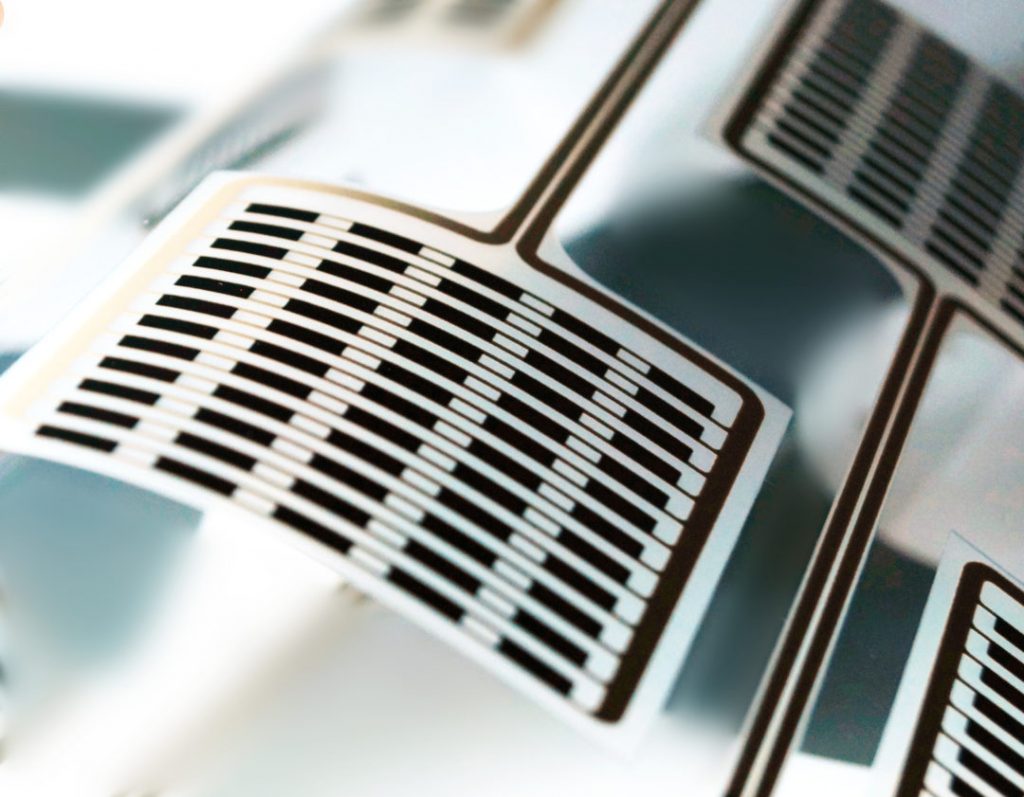

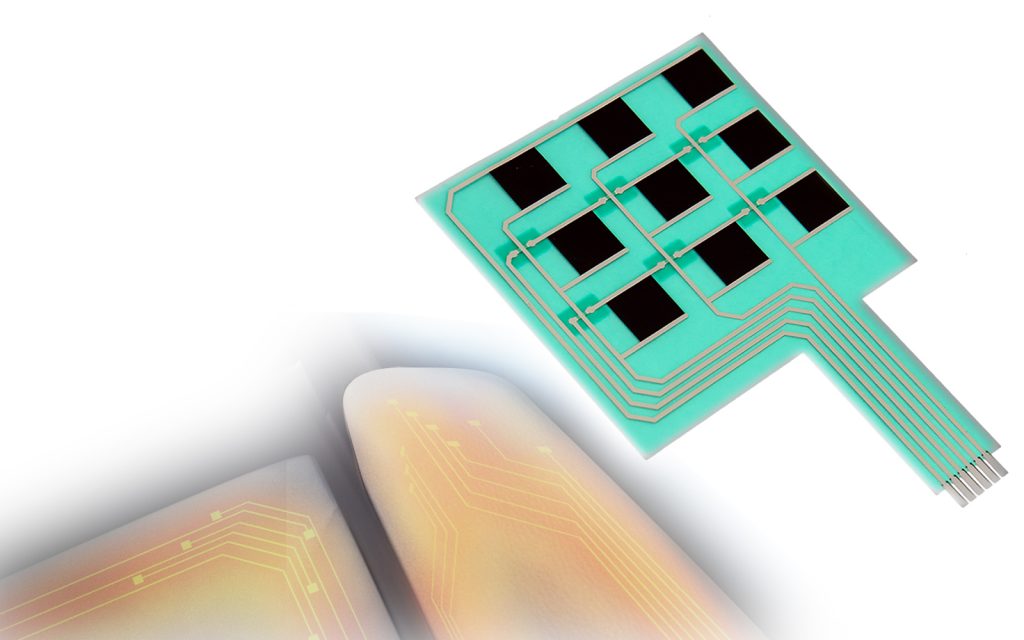

Our mechanical PCUs feature tactile feedback based on micro-switches or metal domes, these products can have a front panel with printed graphics or a silicone membrane with plastic or metal keys. Capacitive PCUs are available with rigid or flexible capacitive sensors that can also deliver tactile feedback, uniform backlighting, and excellent surface scratch resistance.

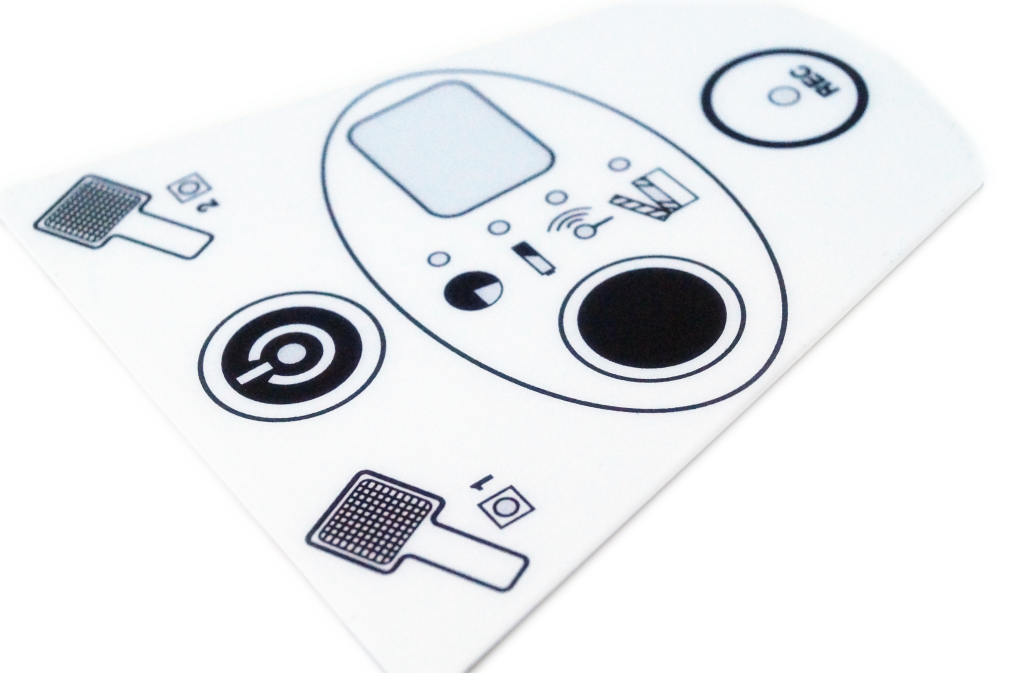

In-Flight Entertainment (IFE) Controls

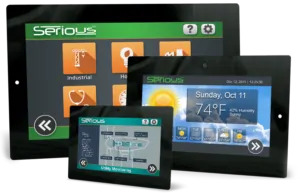

To help passengers to enjoy an optimal travel experience, e2ip technologies works closely with major industry players by offering them innovative interfaces such as IFE remotes, USB chargers, touch screens, and others that can be easily integrated into the in-flight entertainment system.

These ergonomic and intuitive products, housed in injection-molded plastic, offer optically balanced backlighting and the choice between projected capacitive or resistive touch screens as well as numerous switch and force options. IFE controls can be tailored to complement cabin interior designs through numerous options for colors, patterns, textures, and icons.

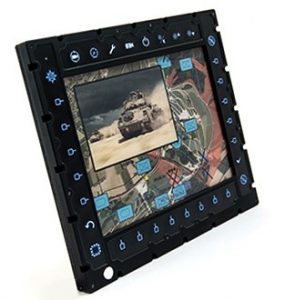

Galley Controls

Efficient and intuitive equipment helps crew members provide airline passengers top-quality service, so it’s important to have controls for cabin and galley equipment that are highly reliable and user-friendly.

Through the use of graphical user interfaces, LCD screen, EMI/ESD shieldings, numerous switch options, projected capacitive or resistive touch screens as well as ample colour, pattern, texture, and icon options, galley controls can be custom-tailored to suit virtually any need.

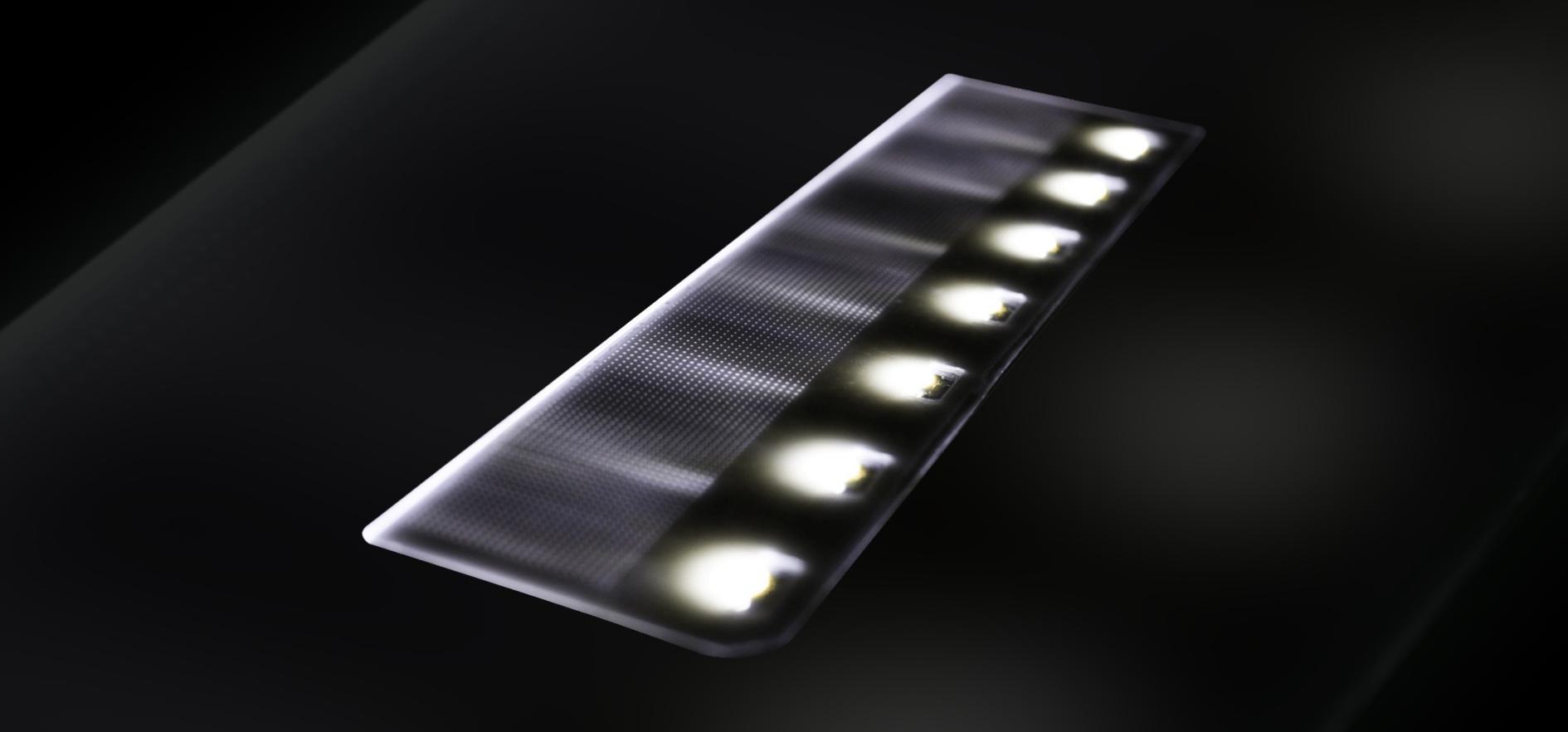

Lighting Solutions

Designed to elevate the cabin interior experience, lighting solutions can be tailored to suit customer branding and designs through customizable textures, finishes, patterns and colors for reading lights, feature lights, ambient lighting, and mood lighting.

With passenger wellbeing at the heart of design considerations, customized lighting solutions create a sense of home and harmony that helps passengers feel at ease.

Signs and Indicators

Well-designed signs and indicators contribute to a positive travel experience by providing passengers with fluid and seamless access to essential information.

Signs and indicators that address the gamut of interior cabin and passenger needs through customizable graphics and various backlighting options in aircraft-rated assemblies can be designed and produced with different colors, textures, and patterns to suit specific needs and contribute to holistic cabin interior designs.

E2IP TECHNOLOGIES Customized Solutions for Cabin Interior Design

At e2ip technologies, safety, quality and reliability are paramount concerns at every stage of product development. This is true whether we’re drafting the initial design, overcoming engineering challenges, or engaging in the final steps in the manufacturing process.

Having achieved top-level certification standards, including AS9100C, RTCA/DO-160, RTCA/DO-178 and FAR 25.853, as well as various manufacturer’s internal standards, such as Boeing and Airbus, our cabin interior products meet the highest levels of compliance across the aerospace industry.

e₂ip technologies received the highly coveted 2020/2021 Crystal Cabin Award for In-Mold Electronics (IME).

By advancing the materials and processes used in IME, e₂ip has unlocked greater design freedom in the creation of elegant, user-friendly surfaces for the cabin space. Through a design that integrates electronics within the molds of controllers, simple hand gestures enable a variety of controls that allow passengers ultimate control over their surroundings.

We create leading-edge product solutions that meet industry standards and exceed customer expectations.

If you want to learn more about our customized solutions, contact us and a member of our team will contact you shortly.