The printed electronics industry has existed for decades, and today, printed electronics are commonly found in almost every modern device. Their lightweight, compact, and flexible design contributes to their widespread adoption across various industries. Additionally, cost-effective manufacturing techniques have made them ubiquitous to the extent they have become almost invisible and often go unnoticed, yet they continue to play a crucial role in introducing and enabling new functionalities, improving product quality, and enriching user experiences.

The industry is once again experiencing a resurgence due to recent innovations and material advancements, leading to new and exciting possibilities, while concurrently elevating and improving existing technologies. One notable advancement is Printed Sensors, which represents a natural progression in this field. Printed sensors seamlessly integrate sensing capabilities directly onto or into electronic devices to detect a wide range of physical and chemical parameters. Their versatility unlocks endless opportunities for innovative solutions in medical, healthcare and fitness applications, offering cost-effective sensor solutions that can be tailored for various use cases.

Biosensors vs Biometric Sensors

In the context of printed sensors used in medical devices and healthcare applications, it is important to understand the fundamental difference between biometric sensors and biosensors. Although both sensors share similarities, their underlying principles and applications are different and distinct.

Biometric Sensors:

Biometric sensors serve the primary purpose of capturing and analyzing unique human and physical characteristics, typically for identification or authentication purpose. These sensors capture and analyze specific biometric data, such as fingerprints, facial features, iris patterns, or voice patterns, and use this information for user identification or verification. Biometric sensors are commonly used in access control systems, identification processes, and security applications.

Biosensors:

Biosensors are analytic devices that convert a biological or physiological response or marker into an electrical signal. Biosensors can be external in nature, such as the glucose strip of a glucose monitoring device, or they can be attached or worn on the human body and are commonly integrated into wearable devices for continuous health monitoring and tracking.

Examples include ECG sensors, which measure and monitor a heart’s electrical activity, EEG sensors which monitor brain activity, and biological sensors that are capable of measuring and monitoring biological substances for biomarkers such as glucose, cholesterol, pH levels, proteins, or pathogens.

Although biosensors are typically non-invasive in nature, they can be designed as implantable devices that offer unique advantages for long-term monitoring capabilities, thereby expanding their potential applications in healthcare.

Despite their differences, the terms “biometric sensors” and “biosensors” are often loosely interchanged because they both involve biological signals and measurements. However, it is important to be precise and contextually aware when using these terms to avoid unnecessary confusion. For the sake of clarity and consistency in this context, we will use the term ‘biosensor’ to refer to sensors that detect and measure specific biological or physiological parameters for diagnostic and monitoring purposes in healthcare.

Changes in Healthcare and the Medical Industry

A Not-So-Distant Scenario

Imagine this scenario: A man is cycling in the park when his wearable sensor detects early signs of a potential stroke, triggering an instant alert. Simultaneously, the information is sent to both his personal AI provider and his family. The AI promptly analyzes the data and administers life-saving medication through a conductive printed patch, which the man already carries for such emergencies.

At the same time, his family receives the notification and acts promptly to offer support and assistance. They have the option to either call for emergency services or rush to his location to be by his side and provide support and assistance. Alternatively, depending on the severity of the event, the man can opt for a nearby solution by riding just 5 minutes to his local pharmacy to get a refill of the printed patch.

This scenario illustrates the immense potential of cutting-edge technology, including wearable biosensors, AI algorithms, and printed electronics, in transforming healthcare and emergency response. With real-time monitoring, quick analysis, and timely interventions, such innovations are poised to improve outcomes and save lives.

The introduction of telehealth and telemedicine marked the beginning of effective outpatient healthcare solutions, enabling remote consultations & medical services outside the traditional healthcare setting. Similarly, the introduction of EMR (Electronic Medical Records) revolutionized how medical data is collected, recorded & stored, with significant benefits in downstream studies and analytics to help aid in identifying patterns, trends and correlations in patient data and predicting outcomes.

The healthcare industry continues to change and evolve and is now making a transformative shift towards “Smart” and connected solutions, driven by a growing need for real-time and remote monitoring in outpatient settings. This shift involves the integration and use of cutting-edge technologies such as Artificial Intelligence (AI), virtual assistance, Internet of Things (IoT), NFC, and wireless networking and communications, and printed electronics and sensors. These advancements hold the potential for profound implications in patient care, not only within medical facilities but also in the realm of in-home healthcare. With mounting strains and challenges on already limited resources, healthcare facilities are actively exploring various options to reduce and mitigate burden and waste, to help optimize healthcare diagnostics and treatment delivery, and to create a more responsive, resilient, and efficient healthcare system that ultimately improves patient treatment and outcomes.

The Potential of Printed Electronics and Printed Sensors

Printed electronics is an innovative and continuously evolving and advancing technology that has revolutionized the design and production of medical devices and sensors. Recent breakthroughs have significantly contributed to the advancement of printed sensors in medical applications:

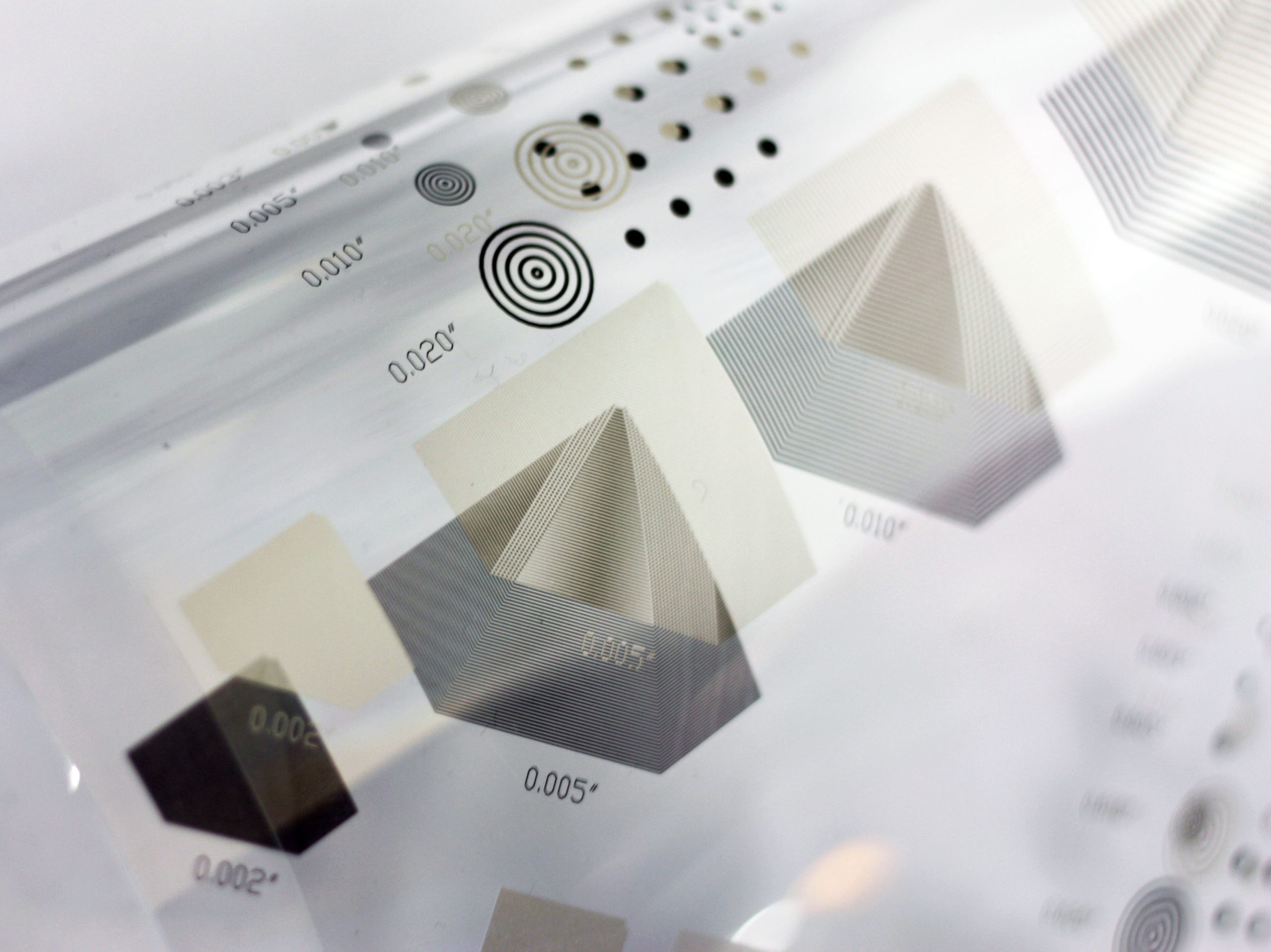

Fine-line Printing: Advanced printing methods and capabilities can achieve ultra-fine printing resolution has enabled the creation of intricate and highly precise sensor patterns. Fine-line printing techniques can improve the accuracy and sensitivity of sensors, making them more suitable for detecting subtle changes in physiological parameters.

Functional Inks: The development of specialized functional inks has expanded the range of sensing capabilities. For example, conductive inks with enhanced biocompatibility and biodegradability have enabled the integration of sensors directly onto or into the human body without causing adverse reactions. Molecular inks can be formulated to offer specific properties and functionalities such as improved sensitivity and accuracy, or to react to specific biological substances or biomarkers.

Transparent Inks: Allows for the creation and printing of near-invisible, discreet wearable devices that can be applied directly to the skin without being visibly intrusive, which patients can wear without feeling sub-conscious. Additionally, transparent inks are well suited for integration into sensors requiring optically clear or transparent/translucent properties, such as heart rate monitors, oxygen saturation sensors, or imaging sensors.

Flexible and Stretchable Substrates: Printing sensors on flexible and stretchable substrates allows them to conform better to the curved shapes of the human body. This innovation has led to the creation of wearable sensors that are comfortable to wear and unobtrusive.

Multi-Modal Sensing: Advanced printed sensors can now detect multiple parameters simultaneously, offering multi-modal sensing capabilities. For instance, a single sensor may measure both temperature and pressure, providing a comprehensive assessment of a patient’s condition.

Wireless Communication: Printed sensors with wireless communication capabilities can transmit real-time data to healthcare providers, enabling remote patient monitoring. This breakthrough has enhanced telemedicine applications and improved patient care, especially in remote or home-based healthcare settings.

Hybrid Integration: Printed electronics can now be seamlessly integrated with other components, such as microcontrollers or batteries, enhancing the overall functionality of printed sensors. This integration enables the development of more sophisticated and versatile medical devices.

The continuous advancements and breakthroughs in printed electronics and sensors have significantly enhanced their potential and applications in the medical industry. As a result, there is a growing adoption of printed electronics and sensors in healthcare, benefiting from their versatility and customizable form factors. These advancements offer many advantages, including quicker detection and diagnosis, improved accuracy and reliability of sensor data, enhanced patient comfort and convenience, self-monitoring capabilities, and cost reduction across the healthcare ecosystem.

One area where printed sensors have had a significant impact is in the development of inexpensive, flexible, and wearable technologies. These lightweight devices can be directly applied to the skin or seamlessly integrated into clothing, enabling various medical applications such as therapies, medicine delivery, and continuous monitoring. The ability to print sensors on flexible and stretchable substrates allows them to conform better to the curved shapes and repeated movements of the human body, making them comfortable for long-term wear.

Moreover, printed sensors can be designed for either long-term use or as disposable applications, with the latter being extensively used in healthcare facilities to reduce infection risks and prevent pathogen transmission. The materials used in disposable sensors are non-toxic and easily biodegradable, making them both cost-effective and environmentally sustainable. Additionally, materials can be enhanced with anti-microbial properties, providing an added layer of protection, and enhancing both patient and caregiver safety.

Sensors play a crucial role in monitoring various physiological parameters like heart rate, temperature, blood pressure, and respiratory rate. Their integration into medical devices and implantable solutions improves patient care, diagnosis, and overall health monitoring in a cost-effective and sustainable manner.

The continuous progress in printed sensor technology is driving a revolution in the medical industry, paving the way for innovative and efficient healthcare solutions. The future holds even more promising innovations that will further transform the medical sector, providing improved healthcare solutions and enhancing patient well-being. Additionally, the convergence of printed electronics and sensors with other state-of-the-art technologies like In-Mold Electronics (IME) will unlock new possibilities and opportunities for growth and advancement in medical devices and healthcare solutions.

Reliable Sensors – Key to Quality Medical Treatment

The design and manufacturing of printed sensors requires multi-disciplinary knowledge and expertise across various disciplines. Additionally, the design and manufacturing of accurate and reliable printed sensors relies on several key aspects:

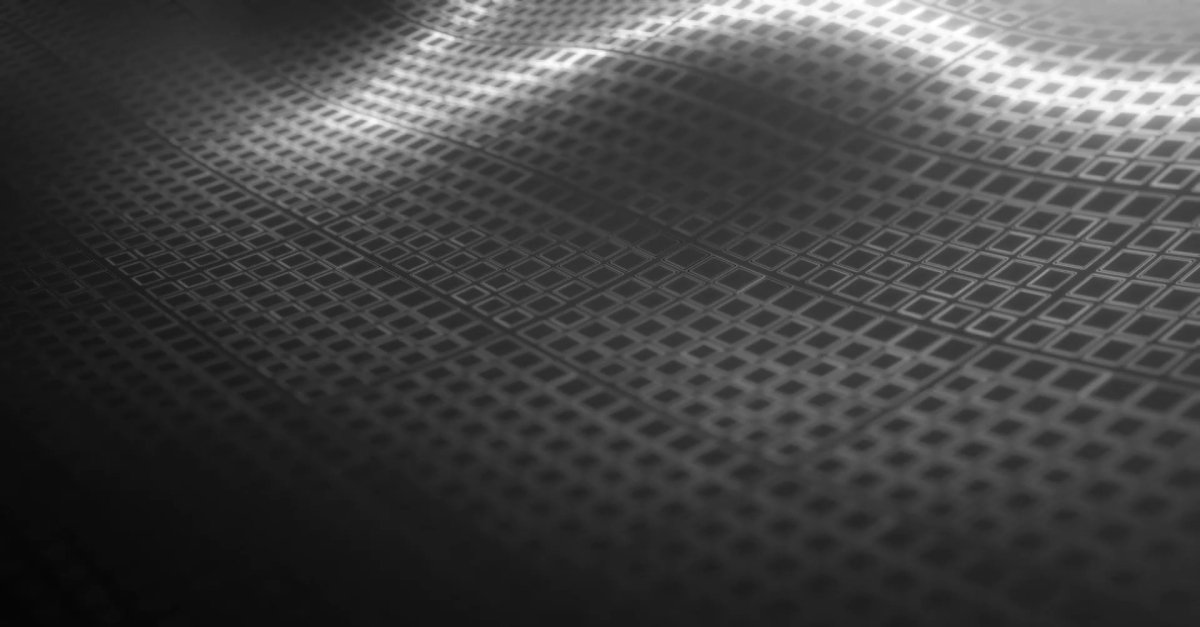

Robust Sensor Design: Creating robust printed sensors requires careful consideration of the unique demands of the intended application. The layout and design of the printed circuit are critical factors influencing the sensor’s accuracy. Key elements like trace width, spacing, pattern and alignment directly impact the electrical conductivity, sensitivity, and signal integrity of the sensor. Additionally, the design must account for the sensor’s long-term reliability and durability, particularly when deployed in real-world medical scenarios, where exposure to diverse environmental conditions or biological fluids is likely. By paying close attention to these design aspects, printed sensors can offer optimal performance and longevity in their intended applications.

Sensor Type and Technology: Selecting and designing the appropriate sensor type and technology is crucial. Printed sensors can come in various forms, including electrochemical sensors, biosensors, strain sensors, and temperature sensors, among others. The choice depends on the targeted application and the parameters to be measured. Additionally, it might be advantageous to design the sensor as multi-model, capable of measuring and monitoring multiple parameters simultaneously.

Material Selection: Choosing the right materials, including conductive inks, substrates, and functional coatings, is essential for sensor performance. The materials should be biocompatible, stable, and capable of maintaining consistent electrical properties over the intended life or usage of the sensor.

Power Consumption: For wearable sensors or remote monitoring devices, low power consumption is critical to prolong battery life and enable extended use without the need for excessively frequent or extended recharging times.

Industry and regulatory Standards :In the design and manufacturing of sensors, it is essential to adhere to all relevant industry and regulatory standards and guidelines. Doing so ensures that the products meet the necessary safety, performance, and quality requirements. By following these standards, manufacturers can produce sensors that are reliable, effective, and compliant with established norms, fostering confidence in their performance and usability.

Algorithms and signal processing: Algorithms and signal processing are essential components in the design of printed sensors. They play a critical role in converting the raw analog signals generated by the sensor into digital information that can be effectively analyzed and utilized for various applications. Raw data often contains unwanted noise and interference, which can negatively impact the accuracy and reliability of the sensor’s measurements. Algorithms are employed to enhance the signal-to-noise ratio, resulting in more precise and dependable readings. By effectively processing the sensor’s signals, algorithms ensure that the data collected is of high quality and can be effectively used for real-world applications.

In the medical industry, additive manufacturing and established printed electronics techniques are used to produce sensors for a diverse range of healthcare applications, resulting in cost-effective sensors and medical device production. As new technologies and advancements are embraced and integrated, the potential for printed electronics in medical applications continues to evolve and grow.

e2ip’s Role in Medical Printed Electronics Innovation

Choosing a reputable manufacturer with practical experience, extensive technical expertise, advanced processing capabilities, and a proven track record and reputation of consistently delivering high-quality printed electronics and sensors is crucial.

At e2ip Technologies, we have the qualifications and expertise required to meet your specific membrane switch requirements. With our longstanding presence as an industry leader and a proven history of innovation, we invite you to get in touch with us today and provide details about your project. We are prepared to address any inquiries you may have, and our dedicated team of experts is committed to helping you find the ideal solution that perfectly aligns with your unique needs.

To learn more about how e2ip can support your need, product, or project in any industry, contact us or call us in the Montreal area at (514) 631-6662 or internationally, at 1-866-631-6662.