Adhesion Solution

Industrial Adhesive for HMI Assemblies

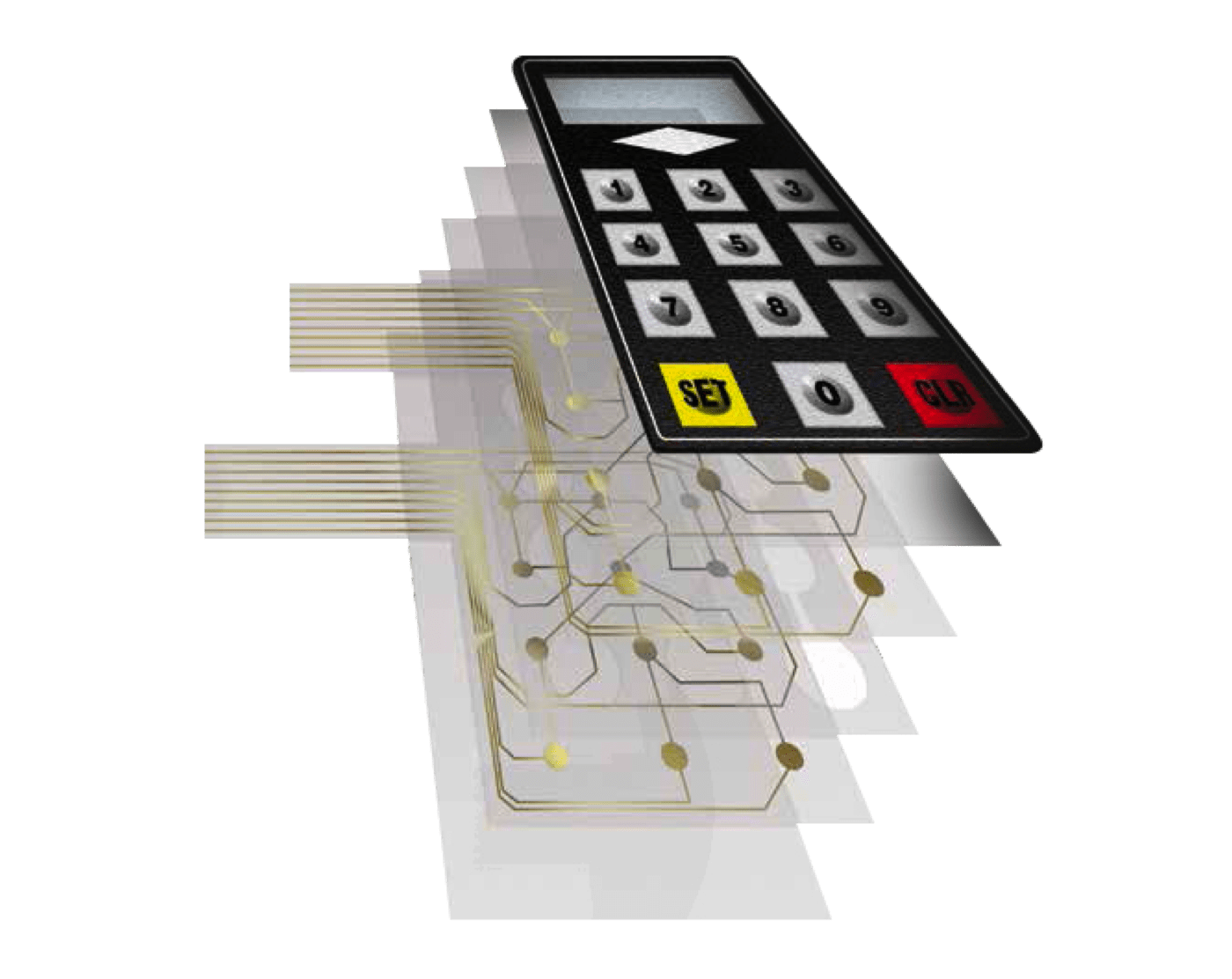

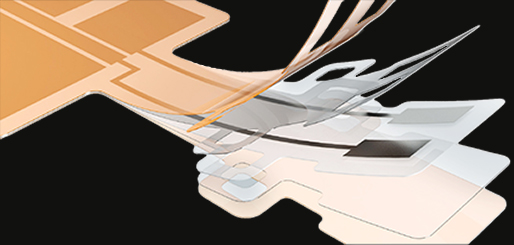

Manufacturers understand that when attempting to meet the exacting requirements of human-machine interface (HMI) assemblies, the final bonding and adhesion of components is a key step in the process.

Achieving sufficient bond strength and flex while meeting industry-specific sealing requirements is not only critically important, it’s also a notoriously difficult engineering challenge, one that many products fail to overcome.

However, through e2ip’s pioneering industrial adhesive solutions, manufacturers can overcome these hurdles, crafting products that blend quality and innovation, and consistently exceed expectations.