Industrial Adhesive Solutions

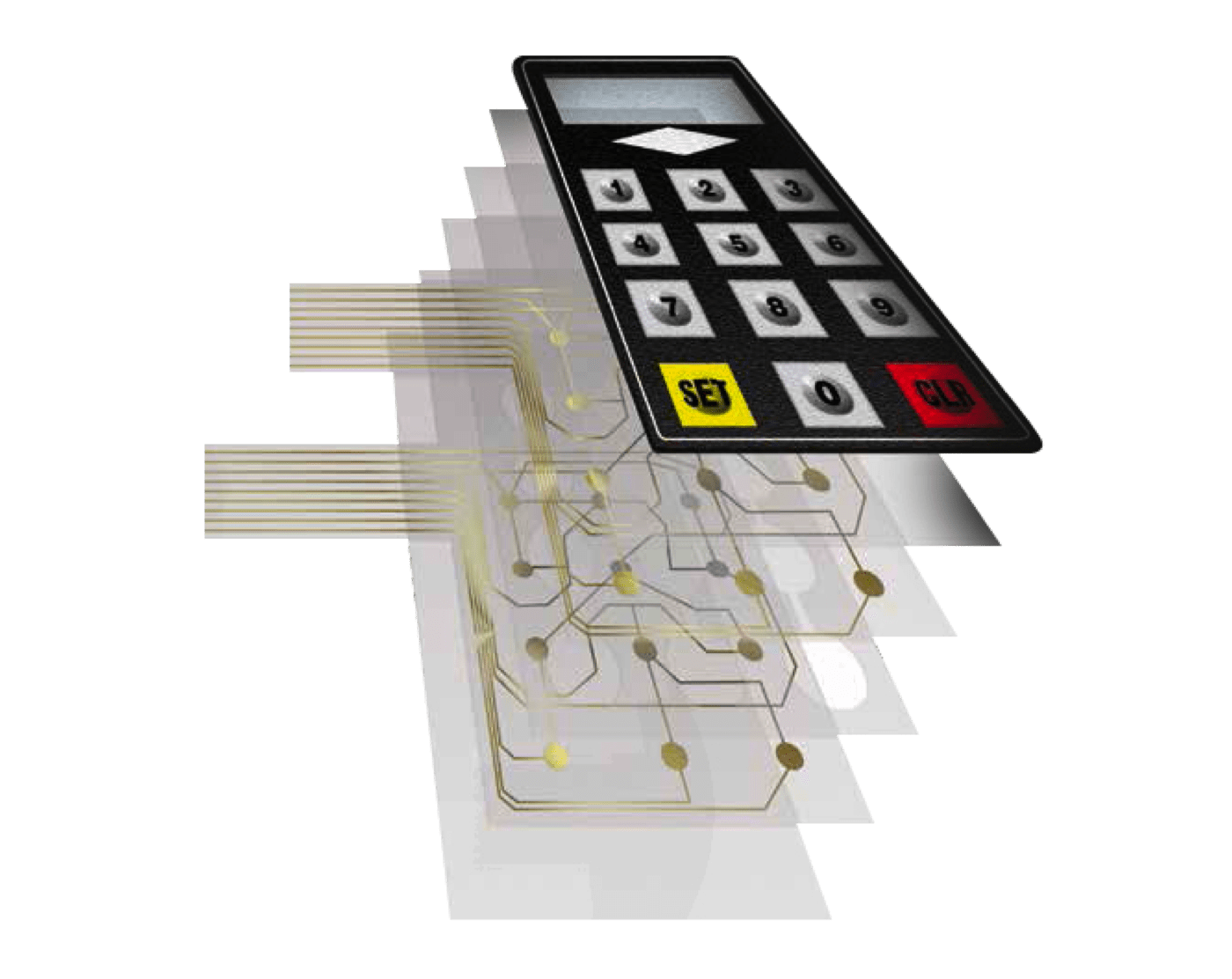

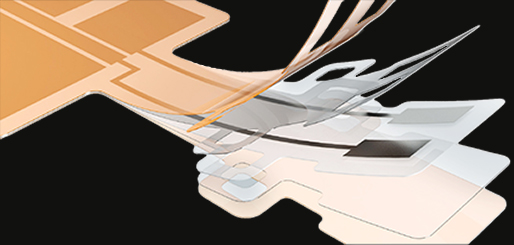

Industrial Adhesive Solutions for HMI Assemblies

The original equipment manufacturers (OEMs) that represent e2ip’s customer base create a wide range of products, each with varying applications. Regardless of their application, each requires a reliable user interface.

However, through e2ip’s pioneering industrial adhesive solutions, manufacturers can overcome these hurdles, crafting products that blend quality and innovation, and consistently exceed expectations.