In-Mold Electronics expands on existing In-Mold Labeling and In-Mold Decorating processes

Before we discuss In-Mold Electronics (IME), the process that enables the production of E2IP’s Smart Molded Parts, we will recognize two processes that have been around for a while. They are In-Mold Labeling (IML) and In-Mold Decorating (IMD). In-mold labeling is the process that creates colours, textures, and graphics for traditional user interfaces.

This idea was carried forward with In-Mold Decorating, a breakthrough that made it possible to apply graphics to an entire surface of an enclosure, rather than simply a limited area.

The In-Mold Electronics (IME) process from industrial design to finished product is made possible through material and manufacturing process breakthroughs.

The manufacturing process begins with the printing of these circuits. This could be a single layer of film or a stack-up of two layers. The pick and place of components is typically the next step. This could include components such as LED’s, passive components and in some cases microprocessor capabilities. The final steps are the thermoforming of the three-dimensional Smart Molded Part and the injection molding. Once the components and inks are aligned on the film, thermoforming can be done by high pressure forming or vacuum forming. After the circuits are checked the formed films are placed in the mold where the resin is then injected between the films enclosing the components to make one single, lightweight, Smart Molded Part that can be attached by screws, bosses, or clips.

Applications & Benefits of In-Mold Electronics

In-Mold Electronics make a whole new world of functionally enhanced products and interfaces possible. With the ability to integrate decorative graphics, lighting, and a host of other features, these Smart Molded Parts of the future are being designed and manufactured to leverage all the benefits and advantages IME provides, including:

- Greater design flexibility

- Improved reliability and durability

- Significant reduction in space and weight

- Improved touch performance

- Ease of assembly

- Sustainability

Quickly gaining popularity in many industries, IME is becoming a crucial component of the next generation of human-machine interfaces, such as:

-

Passenger control units

-

Remote controls

-

Galley insert control panels

-

Cabin management system interfaces

-

Patient monitor systems

-

Home appliances

-

Home security systems

Printed Electronics for Elevated Function and Intuitive User Interactions

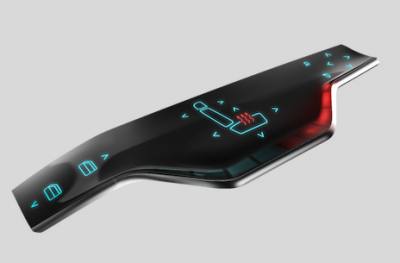

Already a popular choice in premium automotive interiors and aircraft cabins, Smart Molded Parts with IME are also enabling the next generation of white goods, consumer products, and medical technology. IME is a truly transformative technology that will span across industries by seamlessly integrating electronics into sleek and stylized surfaces. IME strips away the mechanical buttons found in traditional electronics, giving designers unprecedented freedom to create elegant user experiences through minimalistic interfaces.

IME makes it possible to create interfaces and devices that not only look alluring but are also lightweight, durable and highly functional. Thanks to fewer moving components, this technology can also reduce manufacturing, assembly, and maintenance costs while reducing the chances of malfunctions or failures.

In-Mold Electronics are suited to wide-ranging applications in aerospace design, medical technology, consumer goods, and more. IME represents the future of human-machine interfaces (HMI).

Want to Learn More About In-Mold Electronics?

At E2IP TECHNOLOGIES, we believe that electronics should not get in the way of design freedom. As a leader in smart molded parts, we can help you realize the transformative potential of In-Mold Electronics for your industry. From ideation to fabrication, we help our partners bring their ideas to life. Our certified manufacturing plants in the USA, Canada, and Morocco, create and deliver cutting-edge products with compliance to the highest industry standards. Our talented, multidisciplinary team goes above and beyond to meet and exceed expectations, every time.

Contact us to learn more.