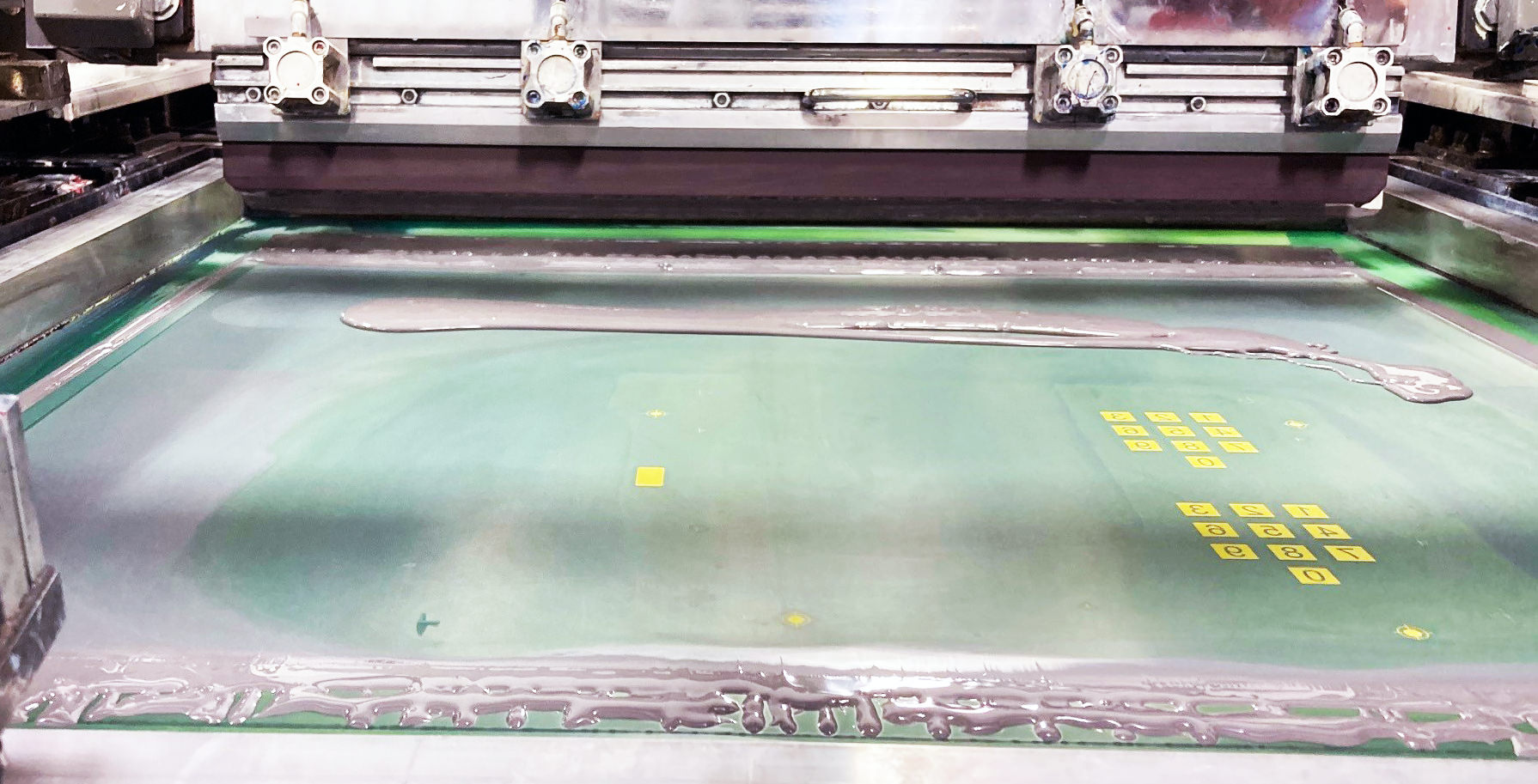

Screen Printing

HMI and Printed Electronics

Starting as a family-run business focused on screen printing over 30 years ago, e2ip technologies continues to expand its screen printing expertise and manufacturing services.

Our proficiency in this field has allowed us to expand our operations and become a leader in printed electronics technologies. Screen printing remains our richest and longest-standing area of expertise, and we continue to screenprint daily at our manufacturing sites.

We attribute our success to a combination of scientific research and strategic acquisitions that have allowed us to innovate and evolve within the realm of screen printing. As a result, we have developed entirely new methods and applications that set us apart from our competitors. Our commitment to quality and innovation has made us a trusted partner for customers in industries ranging from aerospace and defense to automotive and medical devices.