Modernizing first-class rail cabins requires innovation to meet rising passenger expectations. This is accomplished by transforming the first-class passenger experience through innovation and design excellence. Integrating smart, space-efficient solutions into cabins delivers greater comfort, personalization, and sustainability. This strategic focus not only enhances the onboard journey but also reinforces brand leadership in a highly competitive market.

Manufacturers must meet strict safety, performance, and interoperability standards.

Key challenges include

Safety and Fire Compliance: Systems must meet FRA regulations and EN 45545 fire protection standards to ensure passenger safety and material reliability.

Environmental Durability: Electronics must withstand vibration, temperature extremes, and mechanical stress.

Design Efficiency: Replacing bulky mechanical controls with sleek, embedded interfaces requires intuitive, space-conscious design.

Technology Validation: Printed and in-mold electronics must pass rigorous testing to prove long-term reliability in transportation environments.

In close, ongoing collaboration with train manufacturers, we explored several innovative interior concepts. The capacitive passenger control unit presented here exemplifies our approach to combining advanced electronics with refined industrial design for seamless Human–Machine Interfaces (HMI).

Using In-Mold Electronics (IME) touch-sensitive controls are embedded directly into thermoformed cabin panels, replacing mechanical buttons with a sleek, durable interface. A compact touchscreen further enhances functionality by displaying travel data—such as time to destination, weather, and ambient lighting—while offering full customization to reflect operator branding and passenger preferences.

Technical Highlights

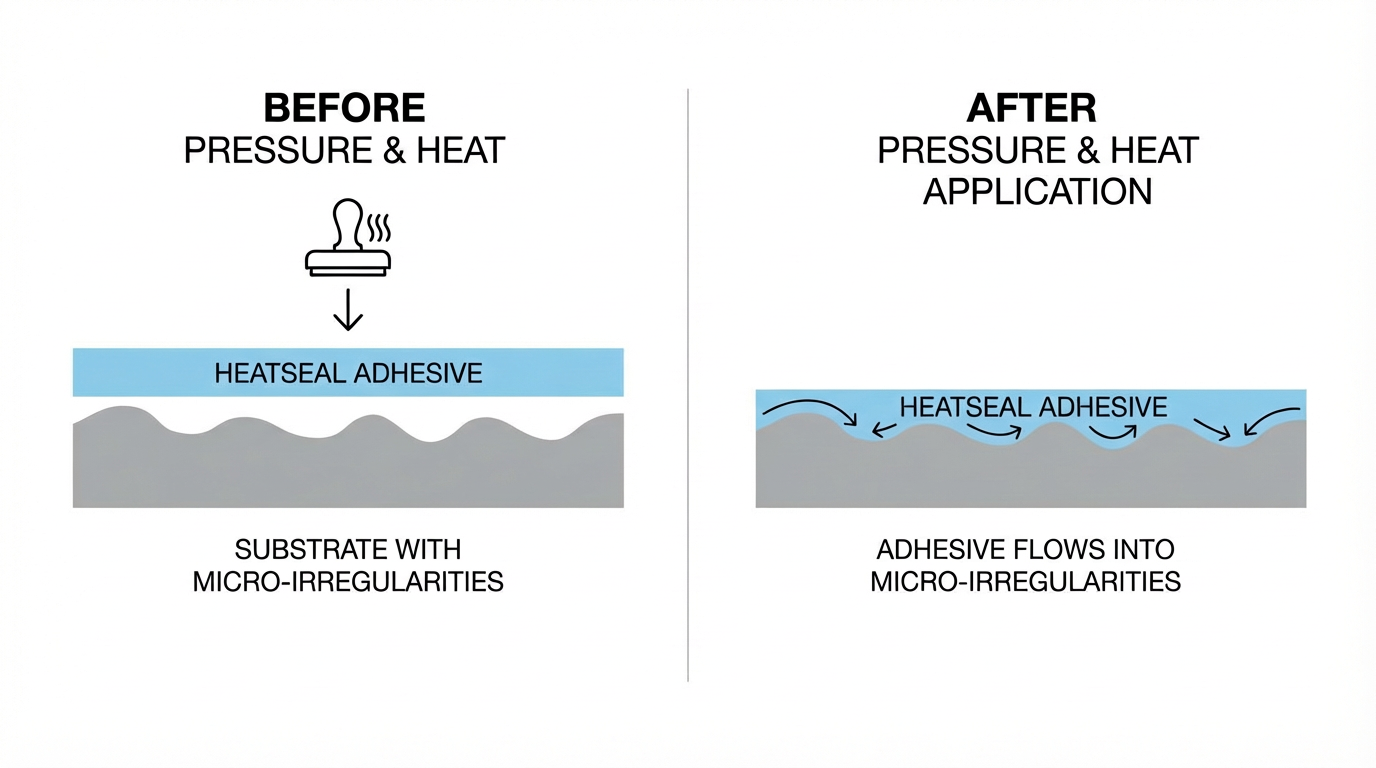

- Printed Electronics: Enables thin, flexible integration of electronics directly into the surface using printed conductive inks and adaptable substrates for intuitive control of seat functions, lighting, and blinds.

- IME Integration: Embeds electronics during molding for a tamper-resistant surface built to transportation-grade durability.

- Embedded Systems: Low-power microcontrollers support responsive touchscreens with real-time data display.

- Custom GUI: Interfaces are tailored to operator branding and designed for passenger ease of use.

- Environmental Testing: Components meet EN 50155 and EN 61373 standards for vibration, temperature, and shock resistance.

e2ip offers a full range of supporting services to ensure successful development and deployment your project. Multidisciplinary design teams guide the process from initial concept to final production. In-house prototyping capabilities enable rapid iteration and testing, while deep expertise in printed electronics and HMI integration supports scalable, cost-effective manufacturing tailored to transportation applications.

If you would like to discuss your project with us please reach here.