As printed electronics become integrated into industrial and commercial products and solutions, the term ‘printed electronics’ is now mainstream. While leveraging printed electronics, e₂ip technologies, has been working in partnership with the National Research Council of Canada (NRC) to advance the material science and manufacturing of In-Mold Electronics. This article offers an overview of these technologies.

What is in-mold electronics?

In-Mold Electronics is becoming a common buzzword in the human machine interface (HMI) industry. Understanding the intricacies between the design and the process of producing a finished IME product is not that common, therefore a simplified explanation will help to understand the benefits of the technology.

Industrial design

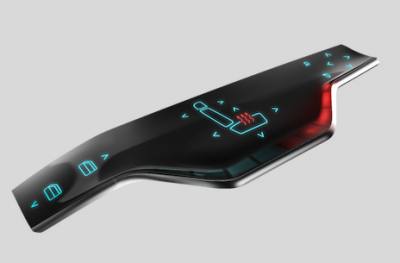

The IME design begins with the creation of a 3D surface via industrial design experts that have vision and intuition as to how a user interacts with a device. From touch, to lighting, to material selection and integration into its surrounding environment, all these attributes go into creating the desired look and feel. This makes surfaces smarter to simplify our everyday lives.

Engineering

Once the part is designed in a CAD model stage, the design is recreated in a 2D format. This is the point where the engineer(s) will step in and utilize electronic skills, printed electronic expertise, connector methods, and lighting techniques combined with printing techniques to create a sophisticated version of a circuit board on a thin plastic film substrate utilizing specialized formable conductive and non-conductive inks.

Manufacturing

When the circuit and graphic designs are completed the actual manufacturing processing steps begin. The first process step is the printing phase which requires understanding the ink chemistries and print layer stack-ups. In some cases, the overall print stack-up is completed on a single film and in others two films are used.

The second process step includes the pick-and-place of components required to add LED’s, passive components and in some cases microprocessor capabilities. It should be noted that depending on the types of ink used, the pick-and-place step could move to a later point in the process.

The third process step converts the flat printed sheet to its intended 3D user interface shape. All inks along with the components on the film end up being positioned exactly where intended in the final shape of the part. Typical thermoforming methods include high pressure forming and in some cases vacuum forming. The films are trimmed, sometimes before molding and sometimes after molding, and the circuits are function checked. Molding is the final process consisting of placing the formed films in a mold, where the resin is injected between the films to encapsulate all the components. This also provides the part with its rigid structure and a means for attachment via screw bosses or clips.

Finished product

From ideation to fabrication, Montreal-based e₂ip Technologies delivers HMI and smart surface solutions to global market leaders.

IME represents the future of HMI in several industries including but not limited to aerospace, automotive, medical, white goods and industrial. IME offers industrial designers the freedom to create a truly innovative user interface with a smooth curved surface that integrates seamlessly into its surroundings. Finished parts are thin, lightweight, durable, cost efficient and highly reliable. Additionally, they are easy to assemble with a streamlined manufacturing process, lower cost of assembly, and a lower carbon footprint.

e₂ip technologies extended IME offering is called ‘smart molded parts’ and can include capacitive touch switches, various illumination techniques, proximity sensors, printed heaters, antennas, and shielding techniques.