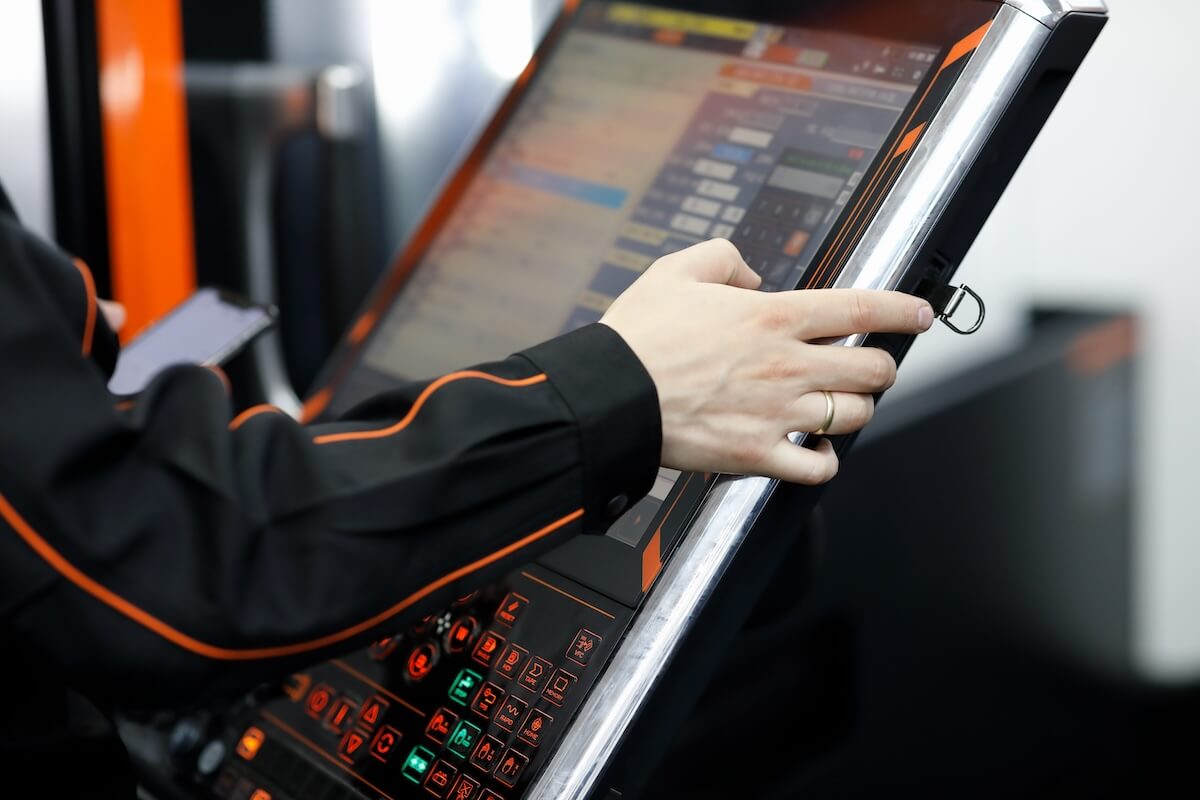

Touchscreens are revolutionizing operational efficiency and human-machine interfacing & machine interactions across various industrial, medical or aerospace environments. From sprawling manufacturing facilities to compact technical workshops, the integration of touchscreens has the potential to provide greater functionality and streamline processes in a wide variety of settings.

In this article, we are going to detail the pros and cons of different types of touchscreens and help you make informed choices based on the requirements of your operations.

LCD and Its Use in Touchscreens

Liquid Crystal Display (LCD) is a generic term that covers a variety of sub-types and variants of technology that is a cornerstone of modern display systems in industrial applications. It utilizes liquid crystals combined with polarizers to control light passage and/or reflectivity at the pixel level, creating the visual output on the screen. This method offers superior energy efficiency and the ability to produce high-resolution images, making it ideal for a wide variety of use cases.

An important feature of LCD screens is their brightness. Measured in nits, the brightness of LCD screens can be adapted to diverse ambient light conditions, from indoor to full sunlight exposure.

Durability stands out as a key advantage of LCD touchscreens. Thanks to the extended lifespan of their backlights, LCDs offer reliable touchscreen functionality, even in environments where they are used frequently. This ensures that the screens maintain their performance over time, making them an ideal choice for settings with high usage demands.

The broad operational temperature range of LCDs highlights their dependability across various environmental conditions. This feature is particularly important for touchscreens deployed in industrial environments, where temperatures can vary widely. LCDs’ ability to perform consistently in such settings underscores their suitability for demanding industrial applications.

LCDs deliver sharp images with a wide range of color depths, enhancing the visual experience. Technologies like in-plane switching (IPS) and multi-domain vertical alignment (MVA) enable these displays to offer consistent color and clarity across different viewing angles. This is crucial for touchscreens in settings where multiple users interact with the device, ensuring a uniform viewing experience for everyone.

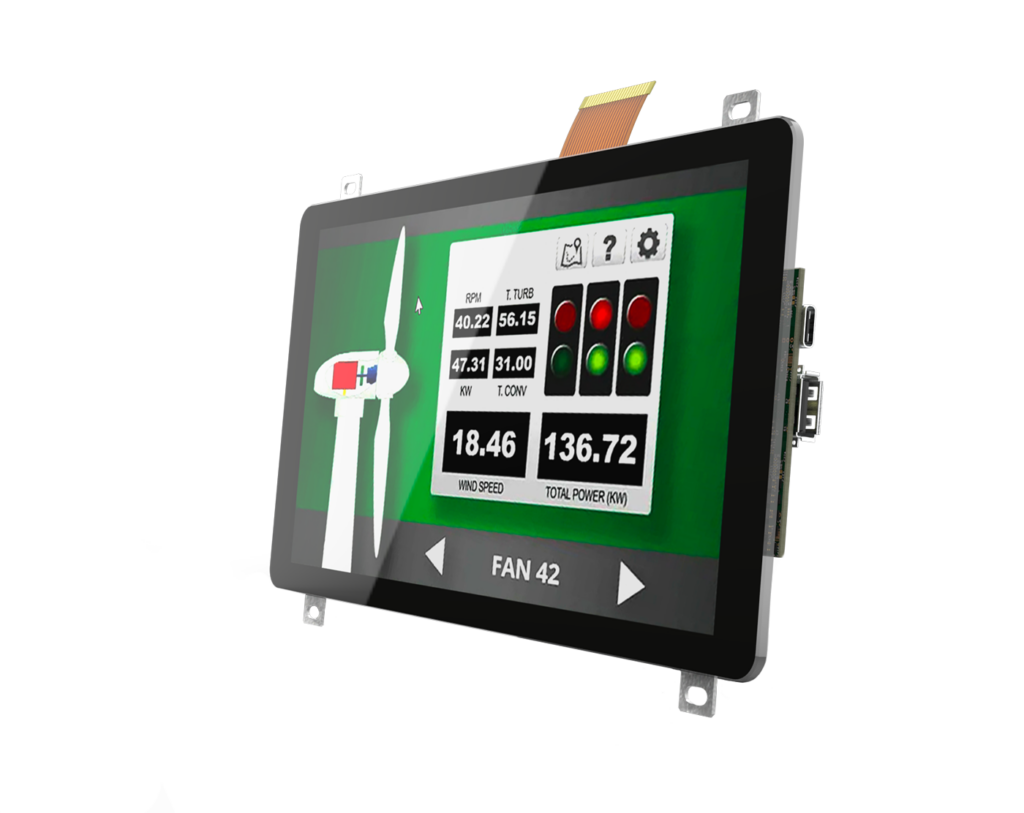

Moreover, resolution plays a pivotal role in the design and selection of touchscreens. While lower resolution displays and touch panels can lower costs, the optimal resolution varies depending on the application. For instance, interfaces with rich graphics demand higher resolutions to ensure visual detail and clarity, whereas simpler user interfaces (UI) and human-machine interfaces (HMI) might not require such high resolutions, benefiting from the cost savings of lower-resolution displays and panels.

The previously mentioned advantages and characteristics position LCD displays as the optimal choice for touchscreen solutions. When integrated with either capacitive or resistive touch technologies, touchscreen display solutions can be customized or tailored to fulfill the demands and specifications of any application in virtually any setting.

Touchscreen Pros and Cons

Touchscreens and LCD displays are distinct technologies that, when integrated, create a comprehensive Smart Touch Surfaces solution. By adding a touchscreen layer to an LCD display, users gain the ability to interact with and make selections on the screen. Just as there are various types of LCD displays, numerous touchscreen technologies exist, each offering its own set of benefits and potential drawbacks. This diversity allows for tailored solutions that meet specific user needs and application requirements.

Like LCD displays, resolution is critical in ensuring accurate touch response; a lower resolution typically leads to diminished touch precision. The optimal resolution for both the display and touchscreen is determined by the application’s unique needs and requirements. Choosing the right resolution is essential for tailoring the technology to provide the best possible user experience and performance, depending on the specific context in which it is used.

Here, we break down the strengths and limitations of two touchscreen technologies offered by e2ip:resistive and capacitive, the latter of which is further divided into surface capacitive and projected capacitive technologies. Surface capacitive touchscreens are designed to recognize only a single touch at a time. In contrast, projected capacitive touchscreens can detect multiple touches simultaneously, allowing for a more dynamic and interactive user experience.

Capacitive touchscreens, known for their heightened sensitivity and responsiveness to touch, are well-suited for advanced applications that rely on touch or multi-touch gestures, such as swiping, scrolling, and pinch-zooming. On the other hand, resistive touchscreens respond primarily to pressure, making them more appropriate for rugged and industrial environments where durability is paramount.

Projected Capacitive Touchscreens (PCAP)

Projected capacitive (PCAP) touch panels use embedded & layered transparent electrode films to create a matrix arrangement with an electrostatic field at the intersection points, and an integrated circuit (IC) chip.

Touch selection or gestures alter the electrical currents at the point(s) of contact, thus enabling multi-touch detection & activation. Projected capacitive touchscreens are more sensitive & responsive then their surface capacitive counterparts, and are capable of detecting even the lightest of touch or gestures.

Pros

- Image clarity: Projected capacitive touchscreens deliver high-resolution visuals, ensuring that your applications look their best.

- Resistant to surface contaminants and scratches: Dust, oil, grease, scratches and moisture won’t hinder performance, making them ideal for heavy use.

- Multi-touch capability: Users can perform multiple touch actions simultaneously, enhancing user experience.

Cons

- Sensitive to EMI/RFI: As with surface capacitive technology, projected capacitive touchscreens may experience interference.

- Somewhat limited activation: Interaction with these screens requires direct touch from an exposed finger or thin surgical or cotton gloves

Resistive Touchscreens

Resistive touch screens feature two conductive material layers separated by a narrow gap of thin & tiny spacer material or dots. When pressure is applied, the two layers make contact, thereby completing a circuit at the point of contact and allow the touch to be detected. Their compatibility with various objects, tactile feedback, and cost-effectiveness make them highly versatile.

Pros

- Compatibility: Resistive touchscreens are versatile, responding to finger touch, styluses, gloved hands, and more.

- Tactile feedback: Users experience a tactile sensation upon touch, offering a satisfying interaction.

- Cost-effective: These touch screens are budget-friendly, making them an attractive option when low cost is a priority.

- Low power consumption: They are energy-efficient and won’t drain power resources.

- Resistant to surface contaminants and liquids: Dust, oil, grease, and moisture pose no threat to their functionality.

Cons

- Lower image clarity: Resistive touchscreens may compromise image quality in exchange for versatility.

- Vulnerable outer polyester film: The outer layer can be susceptible to damage from scratching and sharp objects.

- Can support multi-touch sensing, but not as easily, effectively or accurately as capacitive touchscreens.

- Less or little sensitivity to light touch

- The material of the top-layer of the touchscreen must flex & bend, so it is made of flexible material like polyester or polycarbonate. For this reason, it is more easily scratched or damaged.

e2ip – Optimizing Your Business Through Innovative Touch Technology

Selecting the appropriate embedded systems and HMI solution for your business is a decision of utmost significance. It directly impacts your operational efficiency, user experience, and budgetary considerations.