The Customer

Our customer, specializes in designing and manufacturing equipment and solutions for the medical, dental, and animal health sectors. Founded over a century ago, the organization continuously strives to improve clinical care by integrating physical environments, technology, and operational processes.

The Challenge

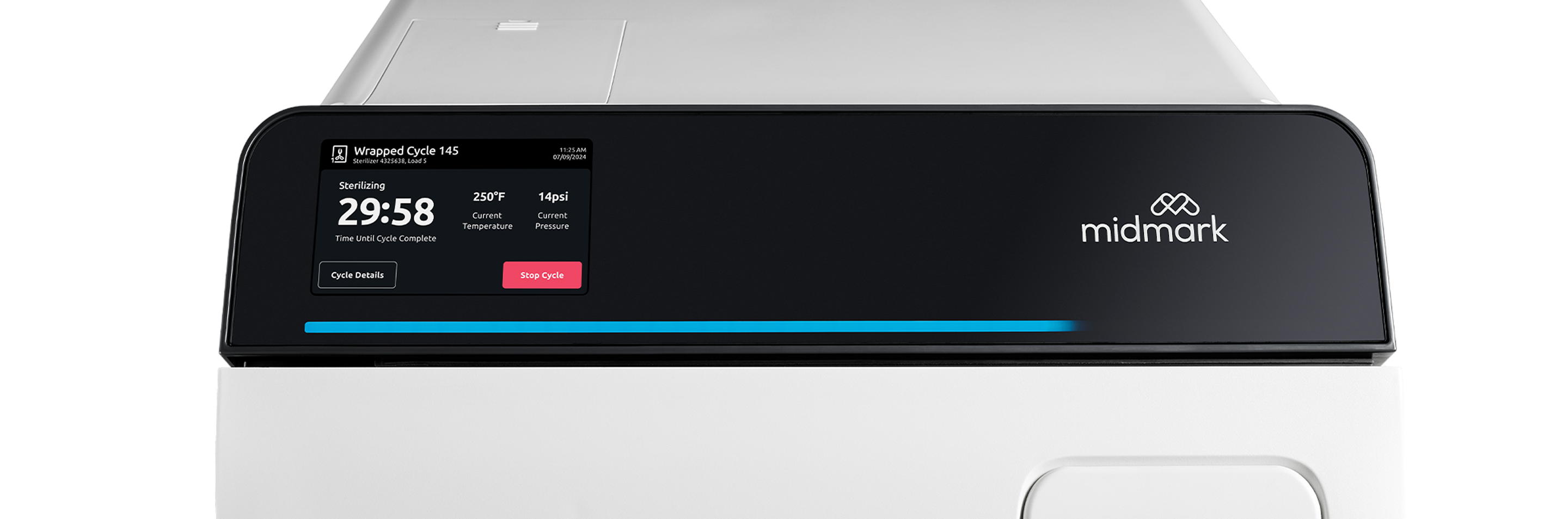

Our customer sought a partner with deep expertise in designing intuitive, high-performance Human-Machine Interfaces (HMIs) for its next-generation steam sterilizer. As a critical piece of equipment ensuring efficient and safe instrument sterilization while meeting strict health standards, the HMI needed to be highly responsive, durable, and user-friendly to withstand clinical demands and address the following key needs:

- Intuitive Interface: Designed for healthcare professionals of all experience levels to use efficiently and confidently.

- Real-Time Data Clarity: Displays up-to-the-second sterilization cycle data for accuracy and compliance.

- Reliability: Built tough to handle heat, humidity, and the rigors of daily sterilization.

- Integration with Existing Systems: Works flawlessly with earlier hardware to ensure a consistent and reliable experience.

Our Solution

Our solution involved several key innovations and differentiators:

- Custom 5-inch Touchscreen: Perfectly sized to fit the panel, maximizing space and enhancing the user experience. Designed for gloved operation, it ensures seamless use in sterile medical environments.

- QT Software Environment: Configured for the customer, enabling easy GUI (Graphical User Interface) creation and customization.

- Integrated Light Bar: A sleek, bottom-mounted bar providing a visual cue for sterilization cycle progress. This adds both functionality and visual appeal, with full customer control.

Unwavering Focus on Reliability and Durability – At the core of our approach was a relentless focus on ensuring the HMI could withstand the toughest conditions without compromise:

- Gasket Sealer Material: We selected high-performance Poron foam to safeguard the entire interface from humidity and liquids.

- Durable Plastic Gasket: Specifically chosen to withstand harsh sterilization chemicals without compromising integrity.

- Rigorous Testing: The HMI underwent extensive Electromagnetic Interference (EMI) resistance and temperature tests to ensure durability and reliability in real-world conditions.

Our customer was particularly impressed with the custom test we developed, which utilized a camera system to inspect the LCD, light bar, and other components—dramatically reducing human error. They also valued our dedication to keeping the project on track through weekly project management calls, ensuring steady progress and swiftly addressing any concerns.